Technical Specifications

Care, Finishing, and Environmental Resilience

Our hardware is crafted from bronze, a living material that naturally evolves through oxidation, transitioning from red-brown cuprous oxide to dark brown copper sulfide, or in high-moisture locations, to a blue-green carbonate patina. We offer a curated range of finishes tailored to either embrace this natural aging or preserve the metal’s initial luster through specialized protection.

The Artistry of the Hot Patina

Our hand-applied hot patinas combine chemistry with fine artistry. By raising the bronze surface temperature to approximately 200°F, we open the metal’s micro-pores to allow cupric and ferric nitrates to penetrate and bond deeply. This heat-driven reaction creates a richly layered, chemically bonded surface where no two pieces are identical, ensuring that each casting carries unique, artistic variations.

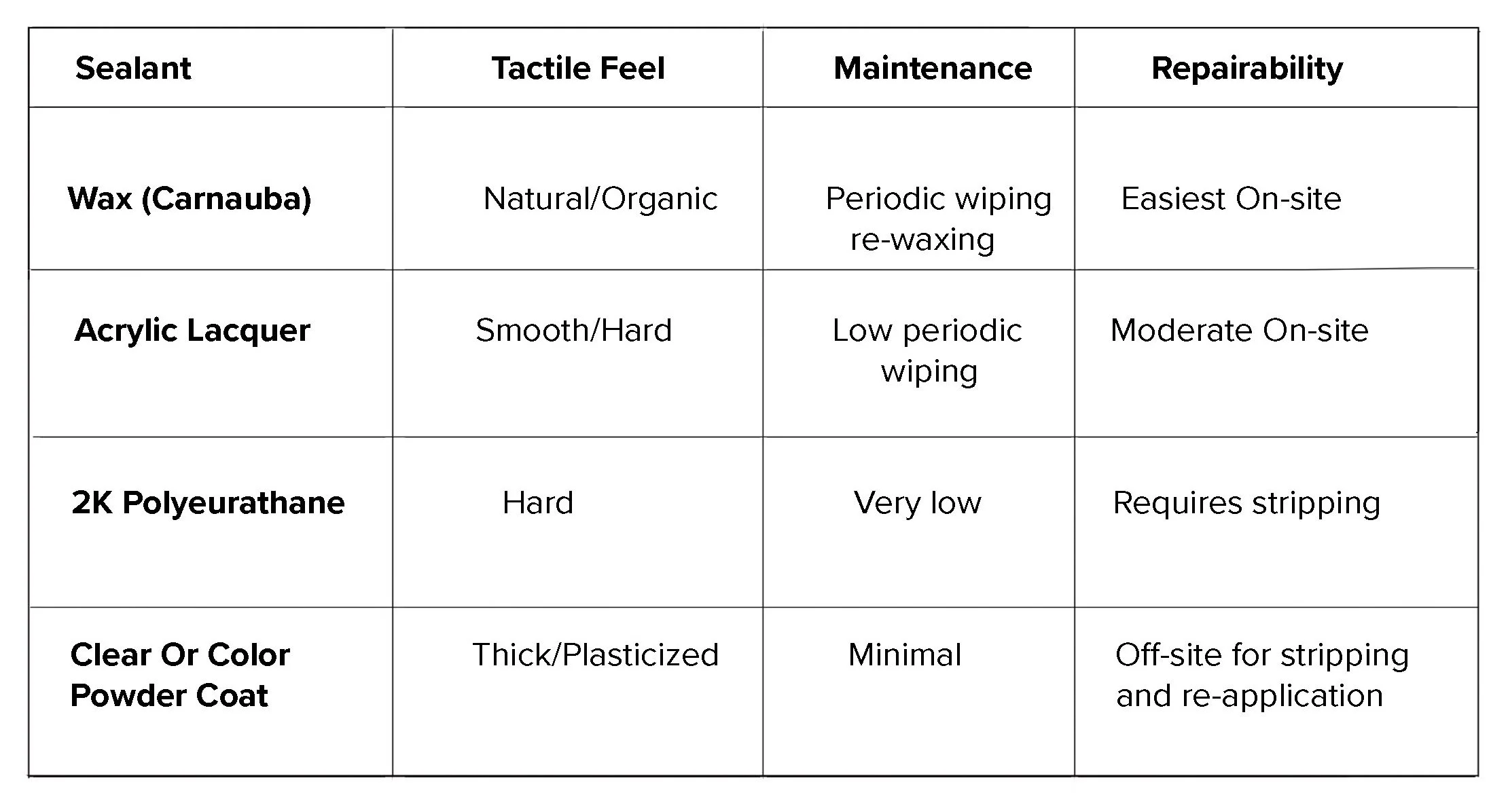

Sealant Specifications

We specify protection based on the project's environmental demands and desired tactile experience. Our traditional Microcrystalline and Carnauba Wax provides a breathable, on-site repairable barrier for a graceful aging process. For high-traffic or coastal environments, we utilize 2K Polyurethane and UV-stable Powder Coatings. These finishes provide a chemically cross-linked, non-porous shield supported by keyed adhesion, where the sealant penetrates the micro-pores of the bronze to ensure a permanent mechanical bond.

Beyond traditional clear coats, we offer Powder Coating utilizing the extensive range of Prismatic Colors who also offer high-precision custom matches to specific brand requirements. These coatings are highly durable and offer a distinct, uniform aesthetic that serves as a modern alternative to traditional hot patinas.

A performance guide for Martin Pierce finish sealants, comparing maintenance requirements and durability for various environmental conditions.

Maintenance Protocol and Marine Selection

To safeguard the integrity of the sealant, we strongly recommend a "soft-touch" maintenance regime. Hardware should never be sprayed directly with cleaners; instead, we recommend using only a microfiber cloth and pH-neutral soapy water. By avoiding ammonia or acidic agents, this protocol prevents chemical pooling, micro-pitting, and the resulting surface damage that often leads to accelerated or uneven oxidation.

For projects in high-saline environments, we typically cast in 316 Marine-Grade Stainless Steel and Silicon Bronze. These alloys are specifically chosen for their resistance to chloride-induced pitting, with our iron-free Silicon Bronze developing a self-protecting patina that acts as a resilient shield against environmental degradation.

Technical Compatibility and Engineering

Our artisan trim is designed and configured for the most trusted locking systems. We provide the technical bridge between bespoke sculptural design and high-security mechanical chassis, ensuring that aesthetic excellence is supported by absolute structural integrity.

Mounting Adaptability and Lock Integration

Recognizing that oversized entry doors are frequently the focal point of modern architectural design, we provide flexible mounting configurations engineered for the unique weight distribution of high-mass doors. Whether a project utilizes FritsJurgens, Rixson, or Dormakaba, we offer bespoke positioning and reinforced mounting with the necessary offset specifications to prevent frame-clash. Since our founding, we have engineered many of our trim solutions to integrate seamlessly with Accurate Lock & Hardware’s heavy-gauge, steel mortise cases. Our operational trim utilizes a square 8mm spindle for a high-tolerance fit, and we support motor-driven electrified locks for advanced access control without compromising artistic definition.

Specialized Applications

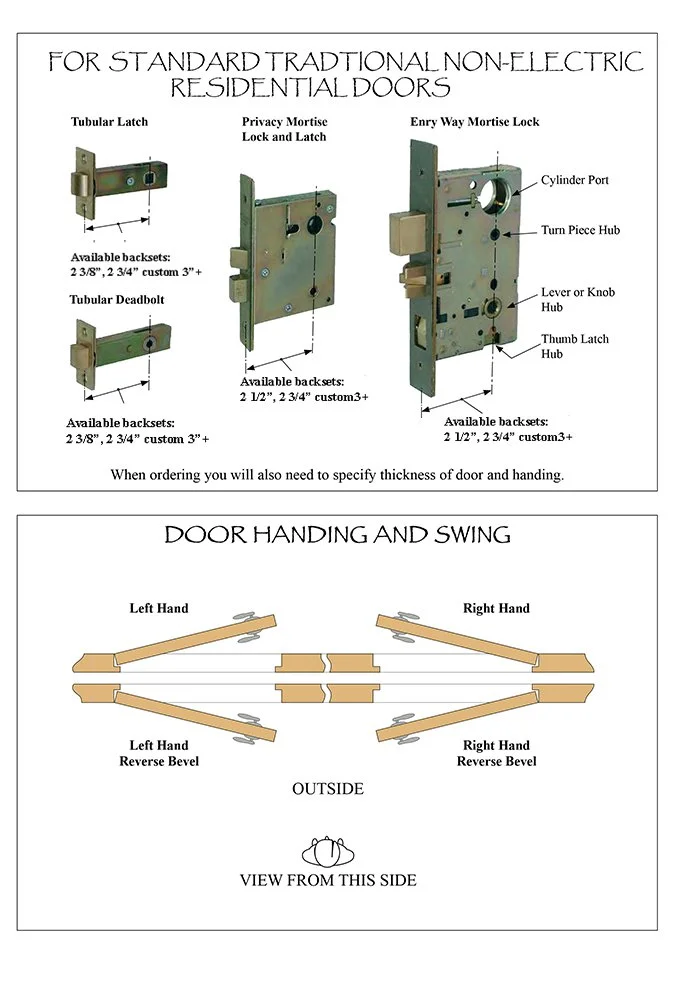

For narrow stiles common on patio entries, we provide coordinated architectural trim for geared 3-point locking systems, custom-tooling internal components to interface with gearboxes from manufacturers such as Hoppe, Andersen, and Trilennium. For interior passageways, our hardware is fully compatible with high-quality tubular latches and deadbolts, accommodating standard backsets as well as integrated privacy functions. In luxury estates featuring custom profiles, we provide extended high-strength spindles for doors exceeding 1-3/4”. For frameless glass applications, all through-bolts are concealed within our custom-cast mounting posts, maintaining a clean aesthetic with no exposed fasteners on the exterior.

For specification support, please provide door thickness, backset, and lock model.

info@martinpierce.com

Standard Residential Non-Electric Doors

Technical diagram illustrating standard door handing, swing orientations, and lock backset dimensions for accurate hardware specification.

Lost Wax Casting

While the hardware industry often relies on high-volume industrial sand casting, our foundry is dedicated to the lost-wax, or investment casting, process. Our approach is defined by the sculptural excellence of the original pattern and a commitment to jewelry-grade detail. By choosing investment casting, we achieve a level of dimensional accuracy and surface complexity unattainable through high-volume commercial methods.

From Hand-Carved Origins to Finished Bronze

Every Martin Pierce collection begins as a hand-carved original in wood, high density foam, or jewelers wax, allowing for an organic fluidity and depth of texture that we believe digital processes cannot replicate. To capture this detail, we utilize high-fidelity silicone rubber molds and a meticulous two-part molding process. We strictly monitor mold longevity, retiring and recreating molds that show any degradation to ensure the final piece never loses its definition. Once poured, wax patterns are coated in a ceramic slurry, fired in a kiln, and then filled with molten Silicon Bronze or 316 Stainless Steel at temperatures exceeding 2000°F. The final result is a near-net-shape casting that requires less hand-finishing to reach its final form.

Global Architectural and Bespoke Services

Our hardware travels far beyond our Los Angeles facility to prestigious locations ranging from the W Hotel in Singapore to the super-yachts of Viareggio. We provide a seamless integration of fine art and mechanical precision, meeting the rigorous demands of hospitality and marine environments.

Signature Commissions and Marine Interiors

For the Post Oak Hotel in Houston, we delivered custom-tooled polished stainless-steel handles and namesake Silicon Bronze grips scaled for 15-foot double doors. At the Baha Mar Resort, we cast 40-inch handles in 316 Marine-Grade Stainless Steel with custom powder coatings to align with the resort's brand identity. Our technical integration is exemplified by our work with the Assa Abloy VingCard system for the W Hotel Sentosa Cove. In the marine sector, we work with firms like SMC Design and Genesis Yachts to develop specialized mounting hardware for deep aluminum fire doors and hollow-core surfaces, ensuring permanent and robust connections.

Cultural Stewardship

Our facility also serves as a technical bridge for cultural heritage projects, such as our collaboration with the Wabanaki Nations and artist Gabriel Frey. By sharing our knowledge of molds and patina development, we transformed intricate carvings into finished bronze handles that met necessary architectural standards while remaining true to the artist’s vision.

Specifications, Templates, and Pricing

We provide digital resources to assist in the specification process while respecting the hand-carved, sculptural nature of our work. Although we do not offer CAD files, detailed tear sheets containing essential dimensions are available on individual product page. To ensure a seamless installation, we provide physical templates tailored to each hardware set with every shipment; these can also be issued earlier upon request to assist with site preparation. For comprehensive planning, full-scale and condensed catalogs are available as PDF downloads on our Pricing Page.

Sustainability and Material Stewardship

At Martin Pierce, our commitment to longevity extends beyond the durability of the hardware to the sustainability of our process. The investment casting method is inherently efficient; the wax that is melted out during the high-pressure steam autoclave phase is meticulously filtered and reclaimed to be used in the creation of new wax sprues, trees, and gates. Similarly, our bronze and stainless-steel production involves minimal waste. The gates and sprues removed during the grinding stages are collected and melted down to be cast again, creating a circular manufacturing loop that respects both the material and the environment.

Lead Times and Project Scale

Because we cast to order and hand-finish every piece in our Los Angeles facility, our lead times reflect the labor-intensive nature of the lost-wax process. For standard residential projects utilizing our existing collections, we typically maintain a production schedule of eight weeks. However, lead times are ultimately dependent on the scale of the project and the degree of customization required.

For large-scale hospitality commissions or truly unique, bespoke hardware designs, such as those created for the Post Oak Hotel or the Baha Mar Resort, the timeline incorporates additional phases for custom tooling, engineering for specific lock chassis, and patina development. We collaborate closely with architects and designers during the specification phase to establish realistic delivery schedules that align with the construction timeline of the project.

For project inquiries, hospitality specifications, or marine applications, please email architectural drawings or relevant hardware schedule excerpts.

info@martinpierce.com

Technical Disclaimer

The technical specifications regarding third-party hardware, including products from Accurate Lock & Hardware, Hoppe, FritsJurgens, Rixson, and Dormakaba, are based on data from the respective manufacturers' official documentation at the time of publication. Reference to these brands is for compatibility and specification purposes only and does not imply a direct endorsement by or formal partnership with the manufacturers. To ensure mechanical alignment, we recommend providing the specific model number of your chosen locking mechanism prior to ordering our trim.