The beauty of the Hollywood Hills, especially in the higher reaches near Mulholland and Hollyridge Drive, is a constant sensory pleasure that starts my day energized and calm. Having walked the hills for many years, I decided to mentally catalogue and digitally record some of the beautiful gateways that front these and other ridges. Whether it is a wooden gate, one of wrought iron filigree, a driveway gate, or a garden gate, all are enhanced by the foliage native to these hills.

Entry Gates

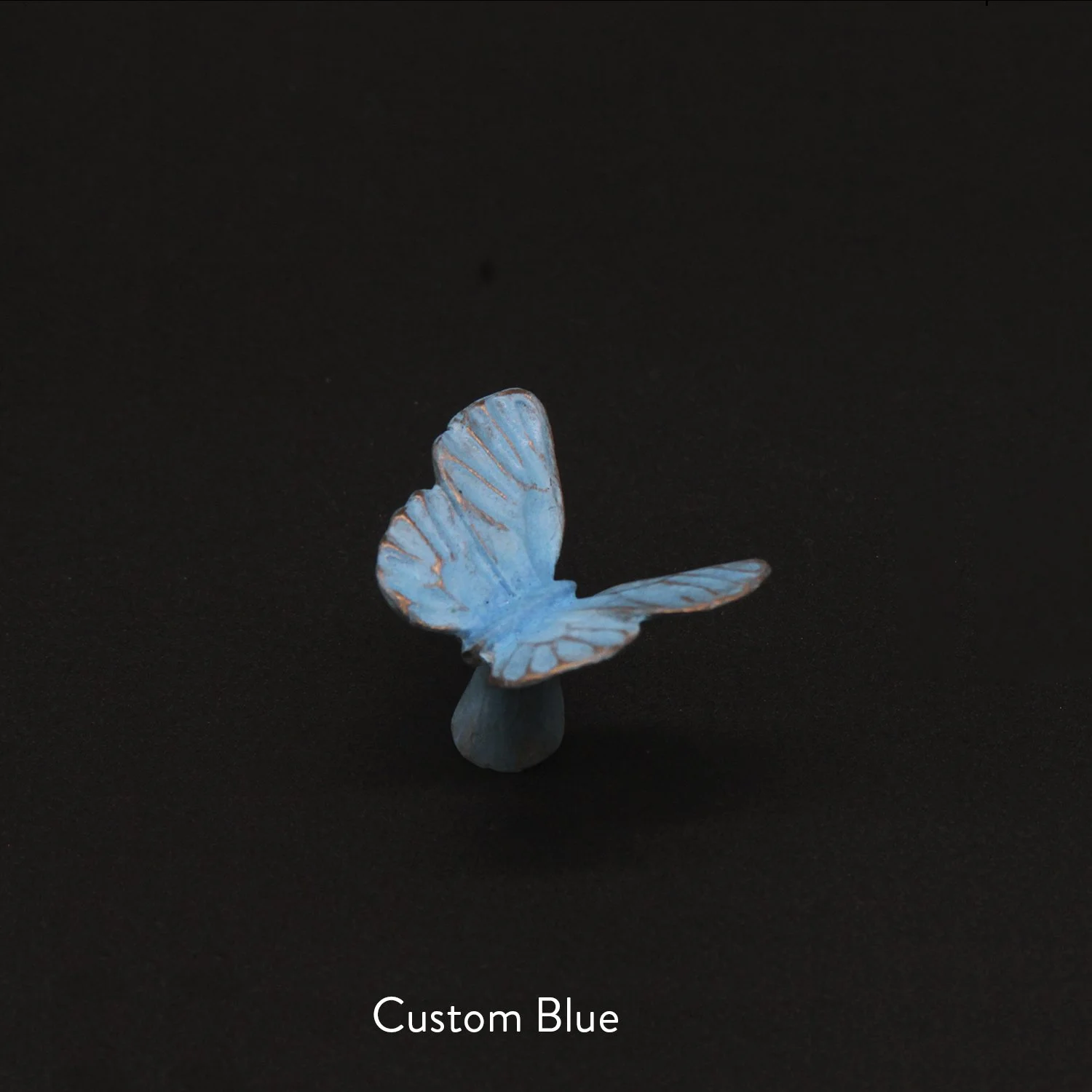

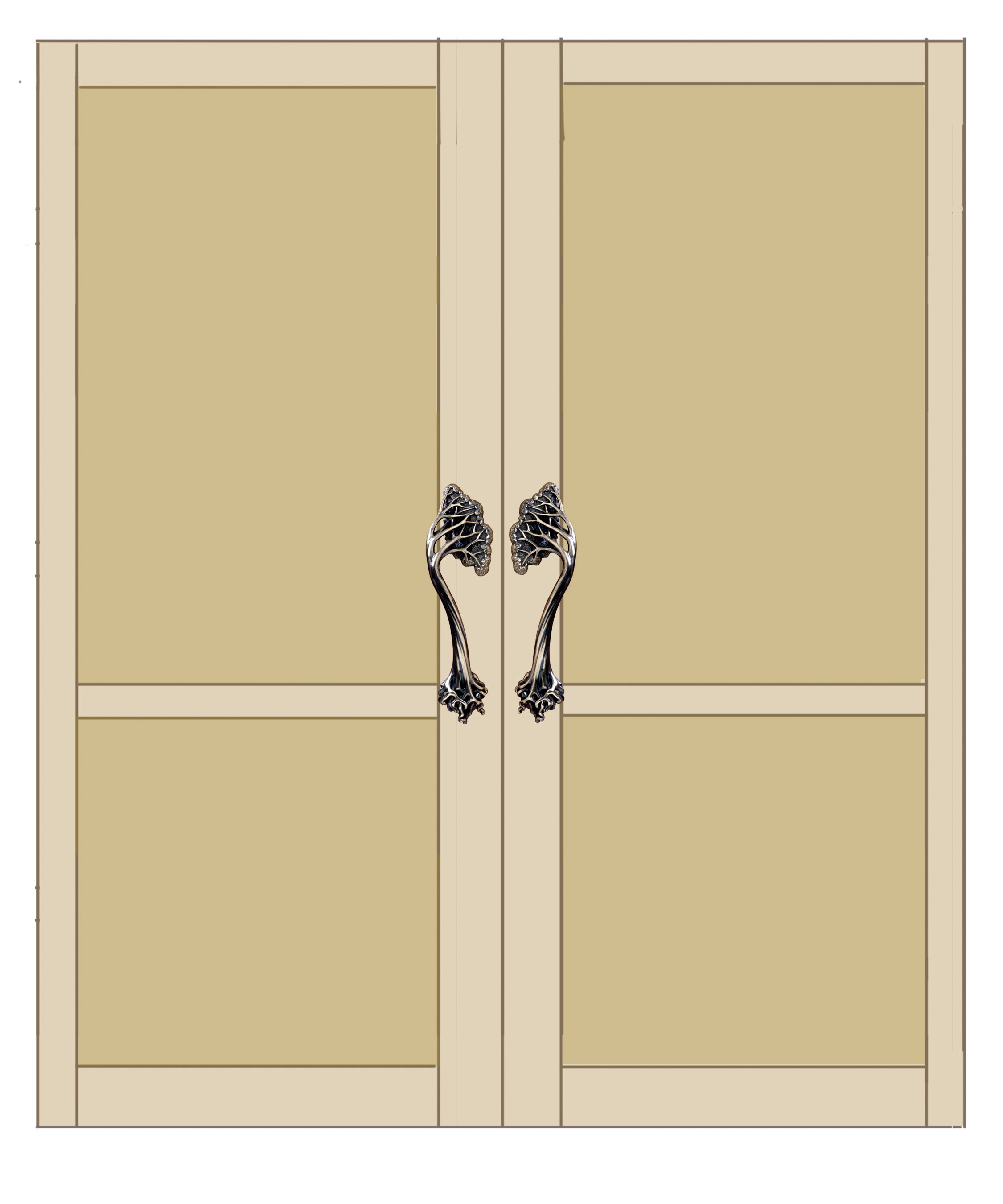

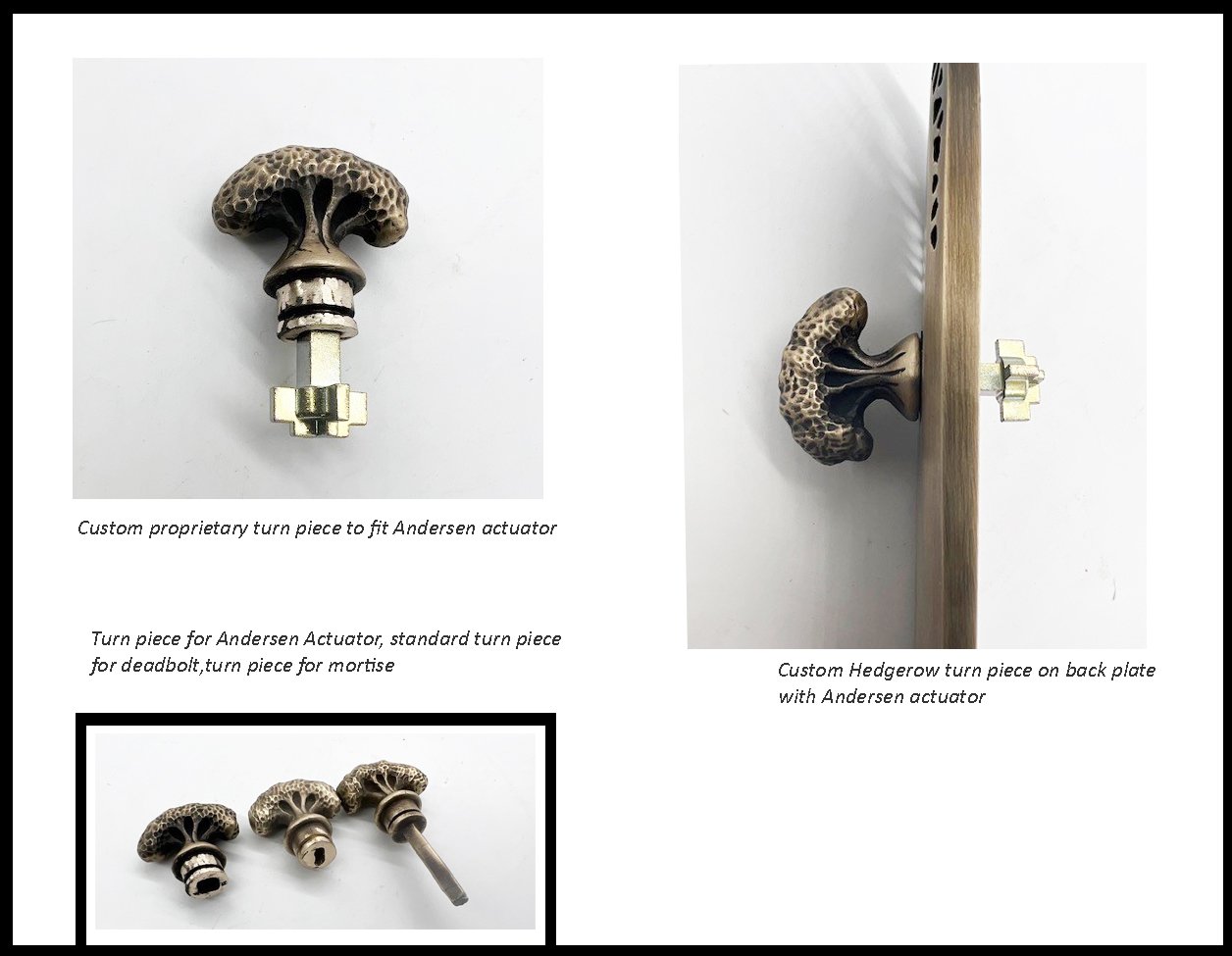

Trumpet flowers and pink bougainvillea encase the custom bronze gate handles on this walnut-paneled entry. The gate’s keyed cylinder, gate lever, and thumb latch are used to activate a secure mortise lock. The large lizard functions as the gate pull, and the butterfly, when depressed with one’s thumb, retracts the deadbolt gate latch that keeps the gate securely closed even if the gate is not key-locked.

The mortise lock, made by Accurate Lock, also has an interesting toggle on the side that, when pushed in, prevents the lock system from locking but allows the gate to remain closed. When the toggle is released, the gate will automatically lock when closed. This is a sophisticated gate system that works well and allows the homeowner maximum control over security, depending on need, from popping out to trim the hedge to fully locking when leaving for longer.

On the reverse side, the locking system is activated by a lizard lever that retracts the tubular latch and by the Beetle turn-piece that unlocks the cylinder and mortise. Since the gate is solid wood and very heavy, it required three sets of 6-inch stainless steel butt hinges. The hinges may have been overkill, as we chose 316 marine-grade stainless steel, but this alloy provides exceptional tensile strength and easily supports the weight of the wide gate.

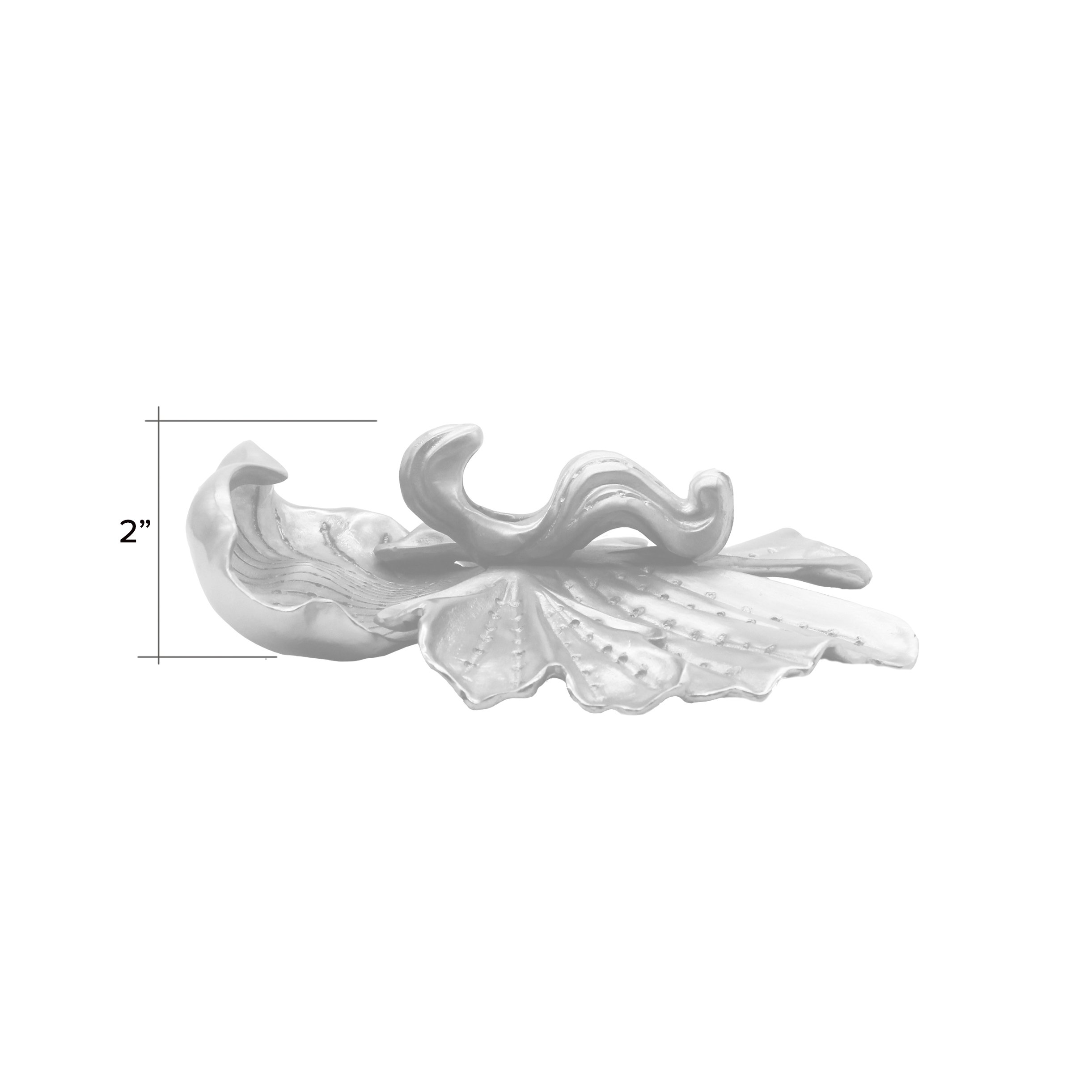

In the entry gate shown here, the lighter weight of the open wrought iron filigree allowed for a more customized and decorative hinge, also fabricated in wrought iron. It is difficult for this writer not to imagine Martin Pierce’s hardware as an alternative lever option, and the Grapevine lever seemed like a good candidate that I would have considered as a complementary style choice.

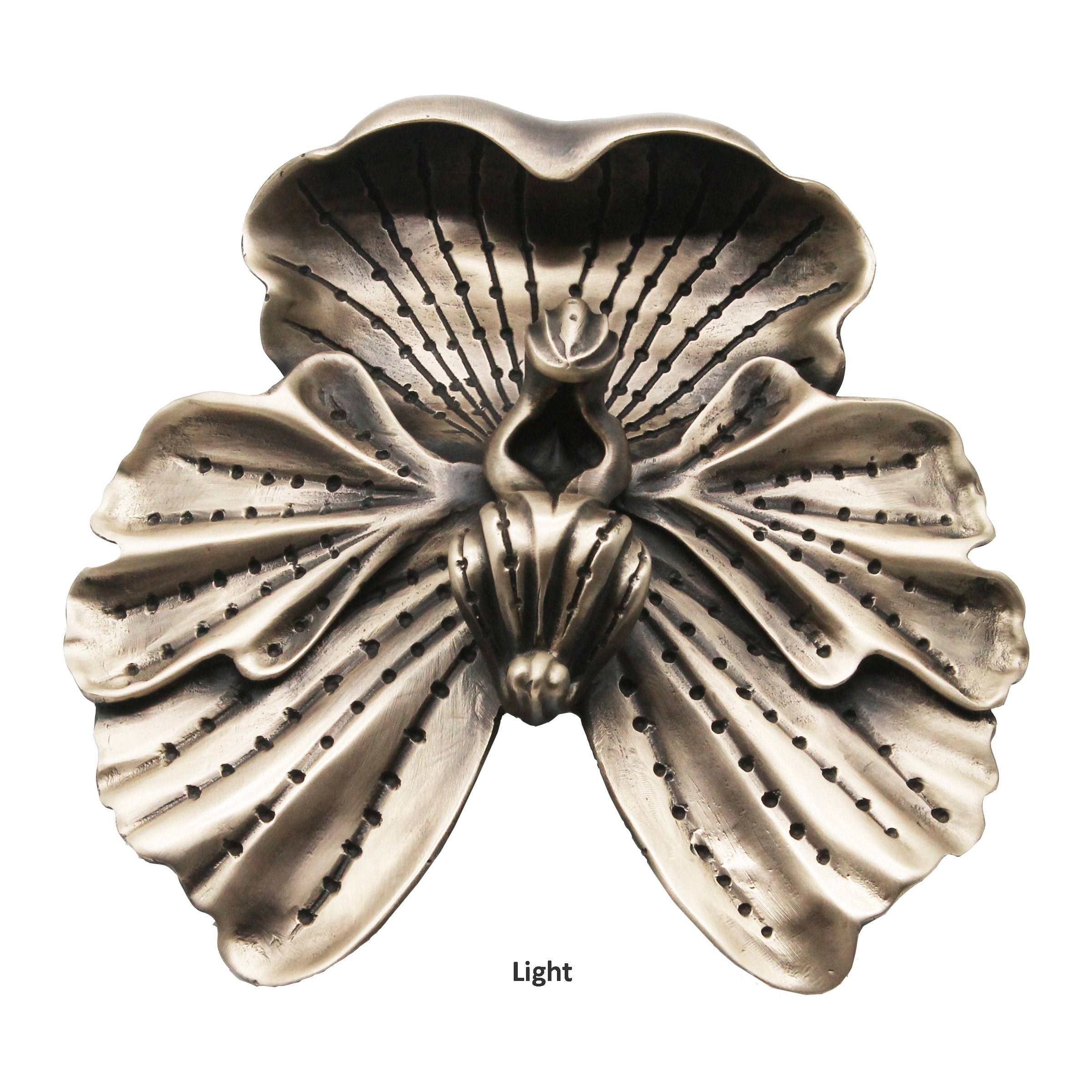

The garden entry gate below is gracefully framed by a mature Ficus, or Indian Laurel Fig, softened by a manicured Boxwood hedge. Though the gate itself seems almost secondary to the lush foliage, an entry knob from the Morphic or Ergo collections could serve as a jeweled accent, much like a pendant that completes a black dress.

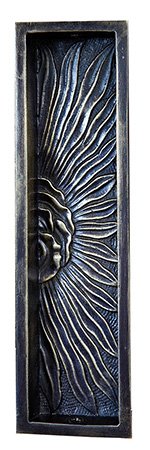

Framed by cascading bougainvillea and set within a deep, keyhole arch, this garden gate reflects the Moorish and Spanish Colonial revival styles that found their way into the Hollywood Hills in the early 1900s, influenced by the nearby Theosophical Society’s Krotona colony. The carved wooden doors, inset with jewel-like circles of colored glass, suggest a mystical quality that distinguished hillside architecture of the time. For this post, I have superimposed one of our sculptural iguana pulls, a piece whose scale and detail echo the whimsical ornament favored in that era, inviting the viewer to imagine how hardware can transform a gate into art.

Not all gates need to be large or custom-made to make a statement. A neighbor of mine chose a simple iron gate, but with the addition of a friendly bronze lizard it was transformed into something both striking and refined. When the gate was first installed, the mailman, who was not fond of reptiles and was momentarily fooled by the realism of this Anole lizard, suffered a moment of panic before realizing the creature was cast in metal.